Cable trays and ladders, connections, related accessories and structures

Application of cable trays

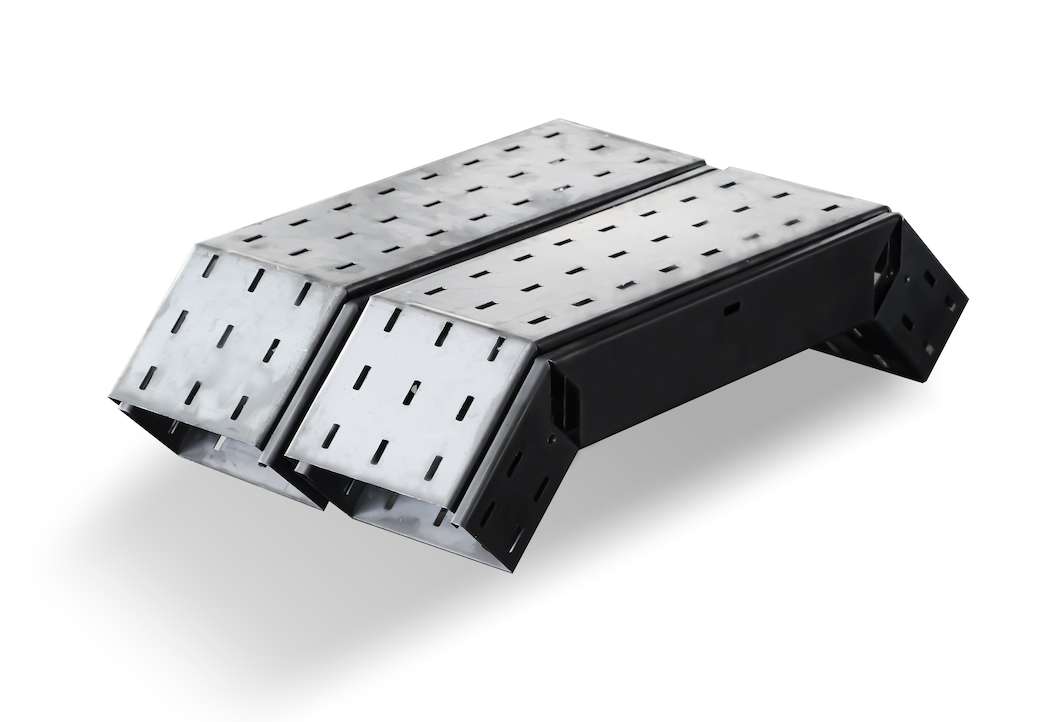

Cable trays are used for cabling in oil and gas sites, petrochemical plants, power plants, commercial and industrial buildings, factories, etc. Cable trays are made of different materials for different weather conditions. For cold and mountainous weather, the cable tray is usually made of galvanized sheet (galvanized fabric sheet), hot galvanized for humid and hot areas, stainless steel or GRP for acidic and humid areas. The hot-dip galvanizing standard in Iran is usually based on ASTM-123A, and the material used is usually ST37 or fabric galvanized sheet. This company manufactures cable trays based on the IEC61537 standard. Steel cable trays are usually made of 304 or 316 or 304L or 316L, which are used in oil and gas sites with high humidity and acidic environment. In recent years, GRP cable trays are used for acidic environments with high humidity because they are cheaper and have higher resistance than stainless steel.

The thickness of the cable tray starts from 0.8 mm and can be made up to 2.5 mm.

Cable tray technical specifications

The production range of cable trays is from 50 mm to 600 mm wide. The height of the wall of the trays depends on the type and size and number of cables that are placed in it. For cable trays with a width of 50 to 100 mm, the wall height is considered to be less than 100 mm, and for cable trays with widths greater than 100 mm, the wall height is considered to be 100 mm. However, AlamAfroze Co is able to produce cable trays with other specifications according to the client's needs.

Cable trays are usually produced in lengths of 2 and 3 meters. They are usually produced with punches. Punching is done so that the cable tray can be installed on the support, and at the same time, punching causes air circulation and cools the cable inside the cable tray. To connect the cable tray, a lap joint or other joints are usually used. This company has the ability to produce cable trays of different materials (galvanized sheet, hot-dip galvanized, steel and GRP) and prepare all related connections for delivery to the customer.

Cable tray connections

The design and production of cable tray connections is based on the bending radius of the cable. The initial proposal of AlamAfroze Co for the production of fittings is usually a radius of 300 mm, but it is also possible to produce fittings with any radius.

All the connections in AlamAfroze Co are produced in two ways:

1- welded connections

2- screw connections

In the welding method, due to the fact that two sheets are placed on top of each other and hot-dip galvanized does not cover them, it is not approved in terms of standards, but AlamAfroze Co has solved this problem by producing integral and bolted connections. It should be explained that GRP joints are produced in the form of bolts and nuts.

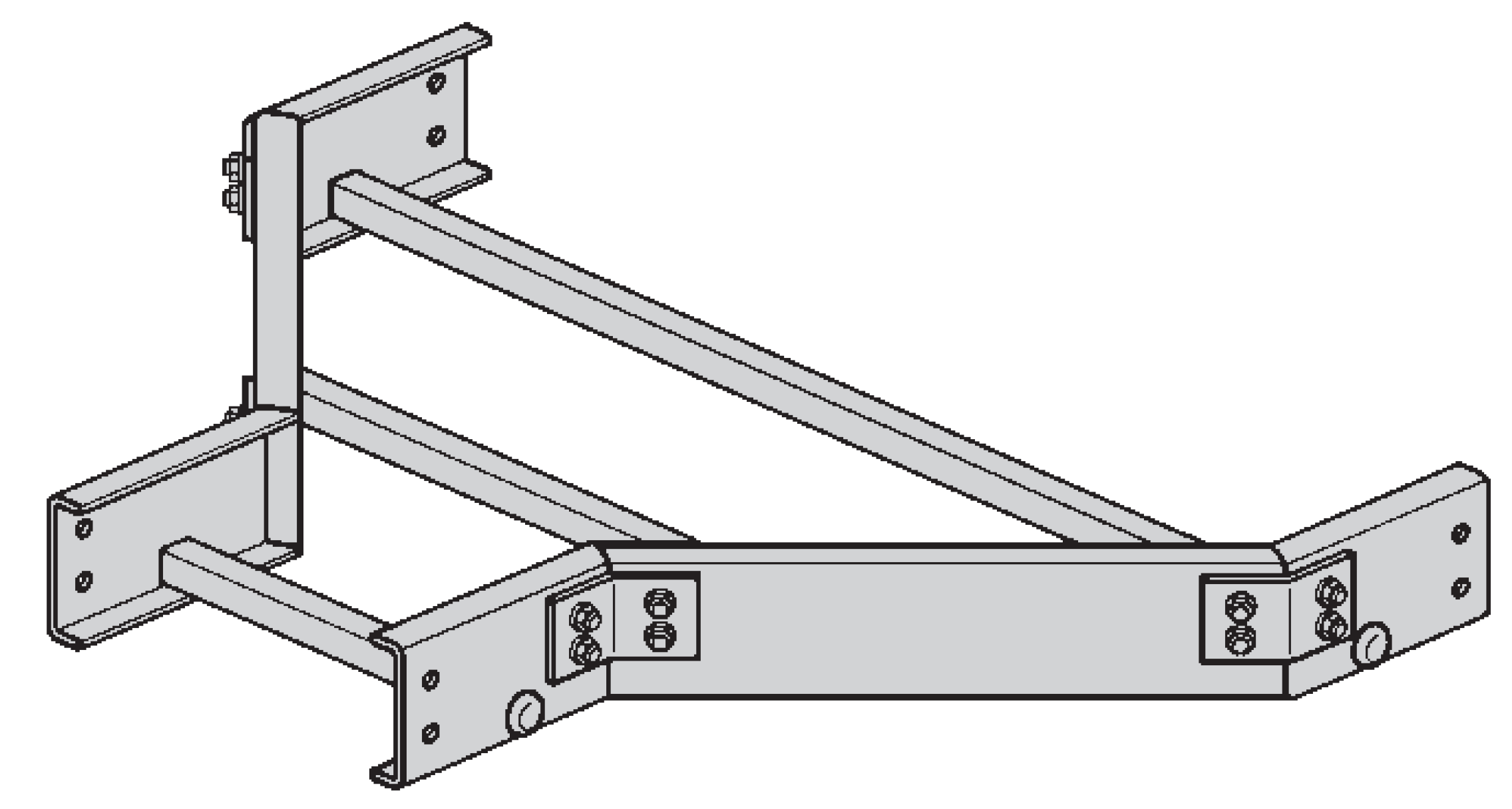

Application of cable ladders

Cable ladders are used for cabling in oil and gas sites, petrochemical plants, power plants, commercial and industrial buildings, factories, etc. Cable ladders are made of different materials for different weather conditions. For cold and mountainous weather, the cable ladder is usually made of galvanized sheet (galvanized fabric sheet), hot galvanized for humid and hot areas, stainless steel or GRP for acidic and humid areas. The hot-dip galvanizing standard in Iran is usually based on ASTM-123A, and the material used is usually ST37 or fabric galvanized sheet. This company manufactures cable ladders based on the IEC61537 standard. Steel cable ladders are usually made of 304 or 316 or 304L or 316L, which are used in oil sites with high humidity and acidic environment. In recent years, GRP cable ladders are used for acidic environments with high humidity because they are cheaper and more resistant than stainless steel.

The thickness of the cable ladder sheet can be from 0.8 mm to 2.5 mm.

The difference between cable trays and cable ladders

The difference between cable tray and cable ladder is the amount of air flow. In the cable ladder, the air flow is very high and causes the cable to cool down. For this purpose, the cable ladder is usually used in the electrical part, and the cable tray is used for the cables of precision instruments.

Cable ladders technical instrumentation

The production range of cable ladder is from 50 mm to 600 mm wide. The height of the cable ladder wall depends on the type and size and number of cables that are placed in it. For cable ladders with a width of 50 to 100 mm, the wall height is considered to be less than 100 mm, and for cable ladders with a width of more than 100 mm, the wall height is considered to be 100 mm. However, AlamAfroze Co is able to produce cable ladders with other specifications according to the client's needs.

Usually, cable ladders are produced in lengths of 2 and 3 meters, and a part called Hold Down Clamp is used to install the cable ladder on the support.

Cable ladder joints

The design and production of cable ladder joints are done based on the bending radius of the cable. The initial proposal of AlamAfroze Co for the production of fittings is usually a radius of 300 mm, but for this company, it is possible to produce fittings with any radius.

All connections in AlamAfroze Co are produced in two ways:

1- welded connections

2- screw connections

In the welding method, due to the fact that two sheets are placed on top of each other and hot-dip galvanized does not cover them, it is not approved in terms of standards, but AlamAfroze Co has solved this problem by producing integral and bolted connections. It is necessary to explain that GRP joints are produced in the form of bolts and nuts.